Hot-Disk

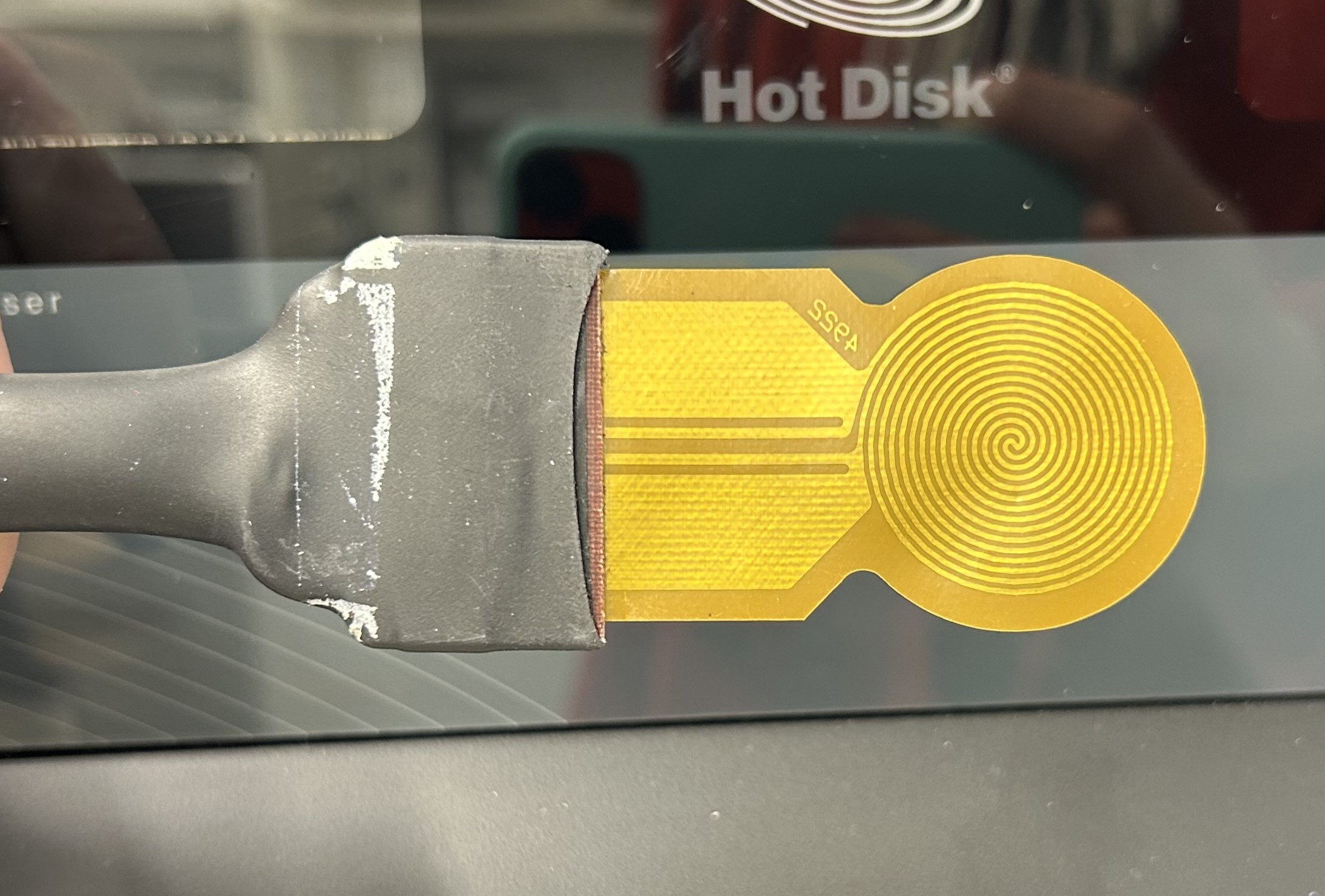

The Hot-Disk operates based on the Transient Plane Source (TPS) method, which is recognized as an accurate and efficient techniques for measuring thermal transport properties. It is an absolute method that provides data on thermal conductivity, thermal diffusivity, and specific heat per unit volume of the material being tested, in compliance with ISO 22007-2. The Hot-Disk sensor consists of an electrically conductive double spiral pattern etched from a thin Nickel foil, which is sandwiched between two insulating material sheets. During a measurement, the plane Hot-Disk sensor is placed between two sample pieces, each with a flat surface facing the sensor. When an electrical current is applied, it generates enough heat to raise the sensor’s temperature by a fraction of a degree to several degrees. Simultaneously, the resistance (and thus temperature) increase is recorded over time. In this way, the Hot-Disk sensor serves both as a heat source and a dynamic temperature sensor.

The Hot-Disk is employed in tests to evaluate materials thermal properties undre different temperature and relative humidity conditions.

Activities

Characterization of Materials Thermal Properties at Microscopic Level

The adoption of the Hot-Disk for thermal property measurements is essential for analyzing the behavior of materials in solid, liquid, and powder forms. The Transient Plane Source (TPS) method enables precise evaluation of thermal conductivity, thermal diffusivity, and specific heat per unit volume. This testing approach ensures accurate and reliable assessment of material performance in various applications.