Climatic Chamber

The Double Climate Chamber consists of two compartments where controlled conditions of temperature, wind, and relative humidity can be reproduced, allowing for the setting of both desired indoor and outdoor environmental conditions. The two chambers are separated within the climatic chamber by the wall whose thermal properties are being analyzed. The external structure of the chamber is made of aluminum profiles, while the inner cell is entirely constructed of stainless steel. This ensures excellent airtightness, while thermal insulation from the external environment is provided by fiberglass panels. The chamber is also equipped with electronic regulators to monitor and control temperature, relative humidity, and air velocity. Both sides of the chamber feature an air-water chiller, which lowers the temperature by compressing and subsequently expanding a refrigerant gas. Additionally, electric heaters warm the internal air. Dehumidification is achieved by exploiting compressed air. Forced air circulation is facilitated by fans that can direct airflow either from bottom to top or vice versa.

To monitor the behavior of the parameters of interest, temperature and heat flux sensors are applied to the sample under test and connected to a datalogger to acquire and store the data collected during the experimental tests.

The Double Climate Chamber is employed in a wide range of activities and tests aiming at the thermal characterization of the building envelope.

Activities

Thermal Characterization of Buildings Envelopes

Test performed on different building envelope samples to characterize their thermal properties and behaviour during winter and summer periods.

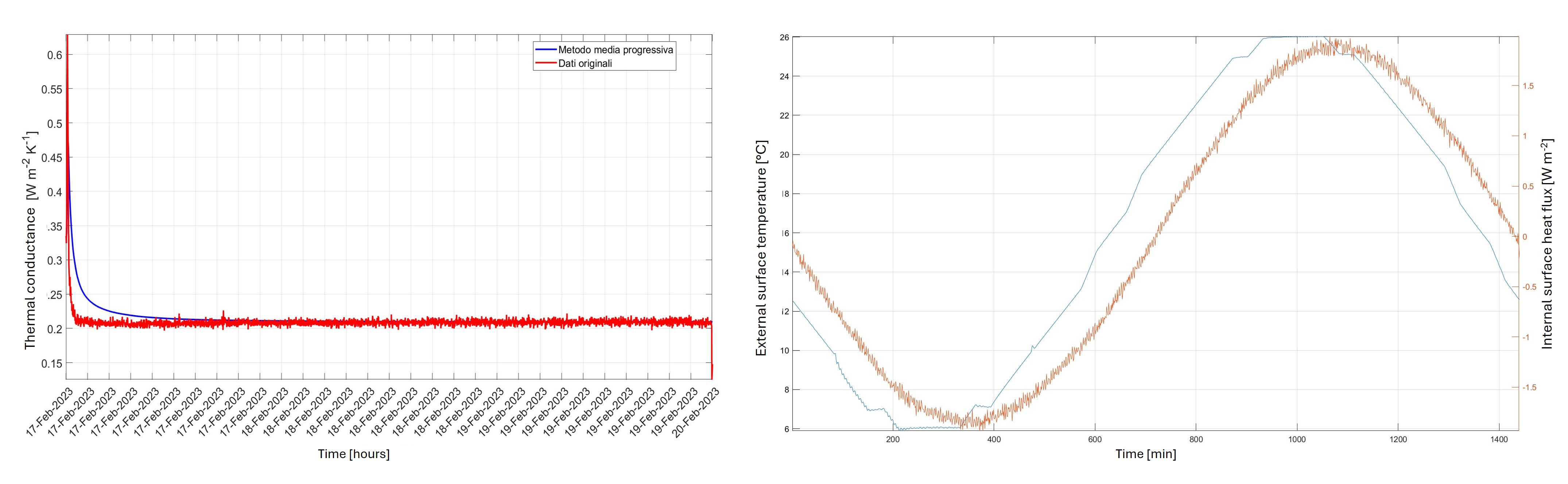

- Thermal performance characterization of the building envelope in steady-state regime: experimental determination of thermal transmittance (U-value).

- Thermal performance characterization of the building envelope in dynamic regime: experimental determination of periodic thermal transmittance, decrement factor and time lag.

Innovative Solutions for increasing Energy Flexibility in Buildings

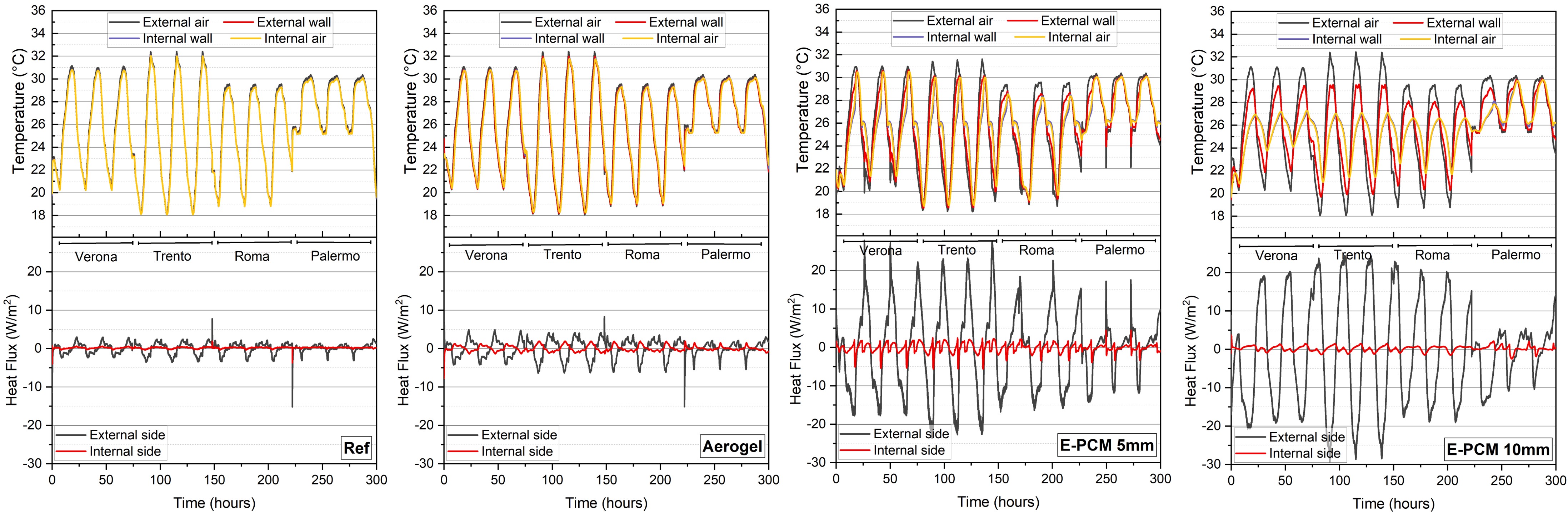

The Double Climate Chamber is employed to support the development of innovative solutions in terms of buildings' materials for enhancing building's resilience. For example: buildings retrofit solutions, building assemblies, innovative materials (e.g., adoption of recycled sustainable materials, phase-change materials (PCM) for studying building energy flexibility, and so on).

Temperature & Humidity Testing

Thermo-hygrometric tests are conducted in the Double Climate Chamber to simulate different environmental conditions, such as temperature and humidity, with the aim to analyze how components respond to this boundary forcing. These tests are essential for determining how a material behaves in a real environment, predicting its durability and useful lifespan in relation to the temperature and humidity variations it may encounter over time. These type of experimental tests are also essentials to study the complex heat and mass transfer mechanism in building materials.

Development of Alternative Procedures for Global Thermal Characterization of Opaque Building Components

Traditionally, stationary and periodic thermal properties are determined through separate procedures. Recent advancements now integrate both tests into a single process, reducing total testing time and improving efficiency. This global methodology saves energy and time, allowing real-time adjustments to wall composition in the design of buildings components within production cycle times.